Scaffolding is an essential tool on many types of construction projects as they provide a safe working platform for hard to reach and height areas. In the UK, performing scaffolding inspections is a legal requirement and is governed under Work at Height Regulations and Provision and Use of Work Equipment Regulations.

Why are scaffolding inspections important?

Due to the risk associated with working at height, inspections are vital. Failures can lead to serious accidents and injuries, even death. Scaffolding inspections check for damaged or missing components, such as guardrails, ties, or boards. It also checks for any signs of instability, such as swaying or tilting, and ensure that the scaffold is adequately supported.

Inspections ensure that the scaffolding is:

- Structurally secure

- Is free from damage and defects

- Can support the intended weight load

- Is compliant with UK Health and Safety Regulations

When must scaffolding be inspected?

Scaffolding should be inspected at regular intervals but should also be inspected if there are any changes. In the UK, the Health & Safety Executive (HSE) states that it’s the users/hires responsibility to inspect scaffolding:

- Following installation/before first use

- At intervals of no more than 7 days thereafter

- Following any circumstance liable to jeopardies the safety of the scaffolding

Who can carry out scaffolding inspections?

Scaffolding can only be carried out by a competent person. This person must have a combination of knowledge, training and experience with the type of scaffolding being inspected and its complexity.

Competence can be assessed under CISRS or through training on a specific scaffold system by a manufacturer or supplier. An individual can also attend an inspection course to become competent.

How to conduct a digital scaffolding inspection with Inspect7®?

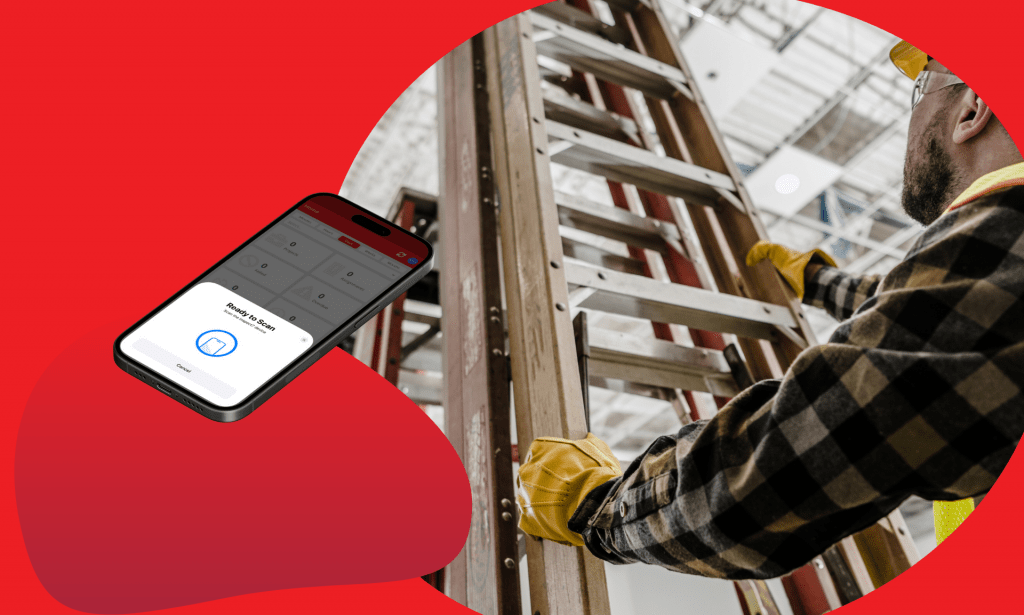

With Inspect7®, scaffolding inspections are brought into the 21st century. Our digital inspection solution uses a tagging system to supplement inspection reports. Simply use the mobile app, which is available in iOS or Android devices, and scan the tag to begin the inspection. A custom questionnaire will be presented to the inspector to complete that can be edited to meet the requirements of the structure and company policies. Images and notes can also be added to the inspection to add additional levels of detail.

Once complete all the inspection data and reports are accessible via the Inspect7® portal. Here users can monitor the status of their scaffolding systems and see when the next inspection is due. Notification can be set up to ensure that an inspection is never overdue, increase the uptime of the structure and most importantly its safety.

To find out more about Inspect7® click here

Meet the Inspect7® devices

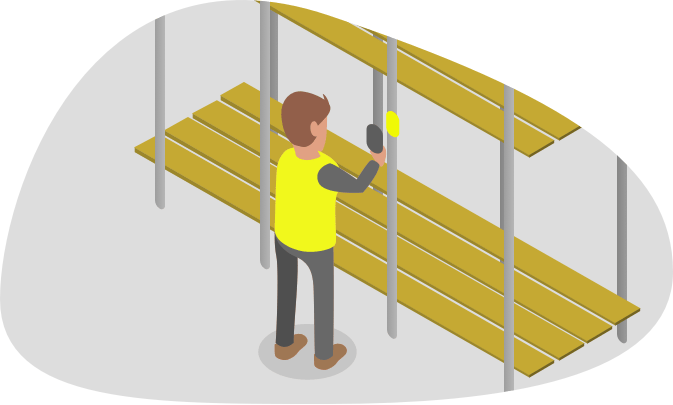

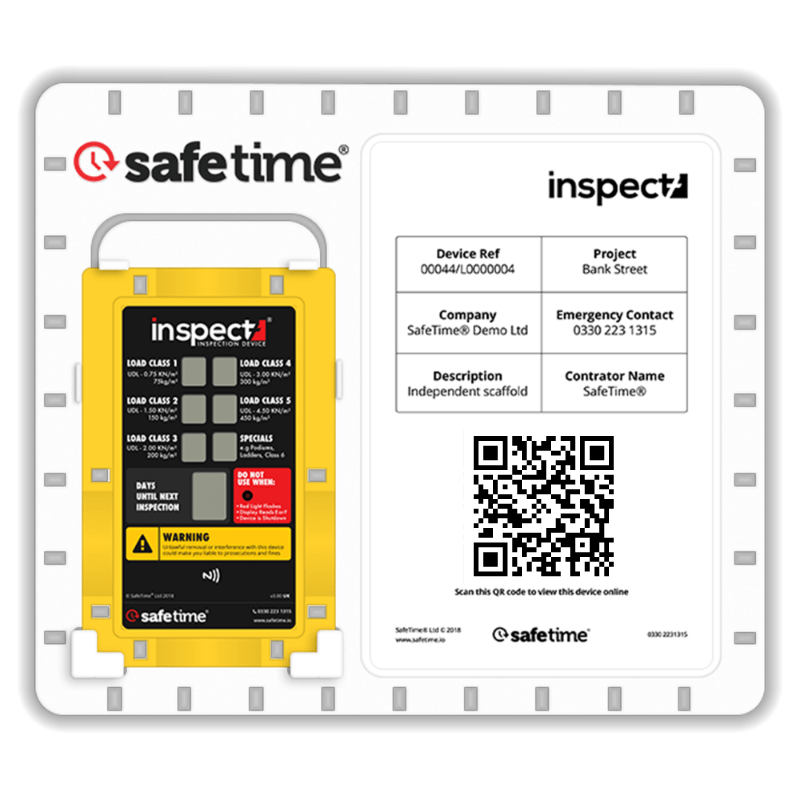

Inspect7® has a range of hardware options available for any type of inspection including our original Device, designed for scaffolding inspections.

Our scaffold inspection device features a display to provide critical system information including load class, a countdown until the next inspection date and a visual indicator for when the system cannot be used. The grooved backplate of the Device is designed to fit snugly on to a scaffold tube or temporary works and be securely fastened with cable ties or other fixings.

To work alongside the Device, there is also the Click-it Backplate.

The Click-it is a mount that is designed to work seamlessly with the Inspect7® Device and Label. A device slot can hold a Device and can be secured to a scaffold via the 32 cable tie points. The Click-it provides additional space to display information about the scaffolding. If enabled, a QR code can be generated through our inspection software and printed. When scanned, it provides access to inspection data of the scaffold to anyone. Additionally, to prevent the use of the system, the Device/Label can be removed from Click-it to reveal a “Do Not Use” warning.

Click here to browse the full range of inspection devices.

Book a Demo