Ladders are a common tool to use when working at height or for access in many organisations in the UK. They are not banned under health and safety law, but they should only be used when the correct ladder system is available and when it is appropriate with a risk assessment. Like scaffolding and other equipment, ladder inspections are required under the Work at Height Regulations 2005 (WAHR) and The Provision and Use of Work Equipment Regulations 1998 (PUWER).

It is an employer’s responsibility to ensure that all ladders and step ladders are suitable for the work task and are in a safe condition before use. The HSE (Health and Safety Executive) states that a ladder should:

– Have no visible defects. They should have a pre-use check each working day

– Have an up-to-date record of the detailed visual inspections carried out regularly by a competent person. These should be done in accordance with the manufacturer’s instructions

– Ladders that are part of a scaffold system still have to be inspected every seven days as part of the scaffold inspection requirements

– Are suitable for the intended use, ie are strong and robust enough for the job

– Have been maintained and stored in accordance with the manufacturer’s instructions

Two types of inspections need to be completed on a ladder before it can be used, a Detailed Visual Inspection and a Pre-use Check.

The two types of ladder inspections

Detailed Visual Inspections

Detailed visual inspections are the employer’s responsibility and should be carried out by a competent person which can be completed on-site. What to look for will be detailed in the ladder manufacturer’s instruction manual, which is used to spot defects and provide insight into the condition of the ladder over time. These inspections need to be recorded and carried out at fixed intervals.

Inspectors will be looking for:

- Damaged or worn feet

- Twisted, bent or dented stiles

- Cracked, worn, bent or loose rungs

- Missing or damaged tie rods

- Cracked or damaged welded joints, loose rivets or damaged stays

Pre-use check

These checks are like detailed visual checks but are completed by the ladder user and are for their immediate benefit. The purpose is to spot defects in the ladder, but it must be completed before the start of a workday, before starting a task or if there has been a change to the ladder such as it being moved to a different location or being dropped.

This type of inspection does not need to be recorded however if the user notices any faults or issues with the ladder then they must immediately report it to a manager.

Pre-use checks and inspection of ladder stability devices and other accessories need to be conducted to the specifications stated by the manufacturer’s instructions.

The Ladder Association suggest that a pre-use check should focus on:

- Stiles – Are the stiles bent or damaged?

- The feet – Are the feet damaged, worn or missing which could result in the ladder slipping? Ensure that the feet are contacting the ground (are not dirty ensuring prevent the feet from contacting the surface)

- The rungs – Are the rungs bent, worn or damaged? Are any rungs missing or loose? Could they fail?

- The locking mechanism – Does the locking mechanism work correctly? Are the components and the fixing bent, worn or broken? Ensure any locking bars are fully engaged.

- Stepladder platform – Is the platform slip or buckled?

- Steps or treads on stepladders – Are they contaminated? Are the fixings loose?

Digitise your ladder inspections

Take your ladder inspections to the next level with Inspect7®. By digitising your safety inspections, not only will you increase the safety of your staff but also reduce the administration and storage of reports.

Less Paper, More Data is a key principle with Inspect7®. By using digital inspection software creating, filing and securely storing reports or manually scanning them into a system becomes a thing of the past. All inspections conducted on a mobile device are uploaded to our cloud-based service which means that reports are immediately accessible when required. Within these inspection reports, images can be attached so the laborious task of finding and collaborating images from mobile devices or cameras is defunct.

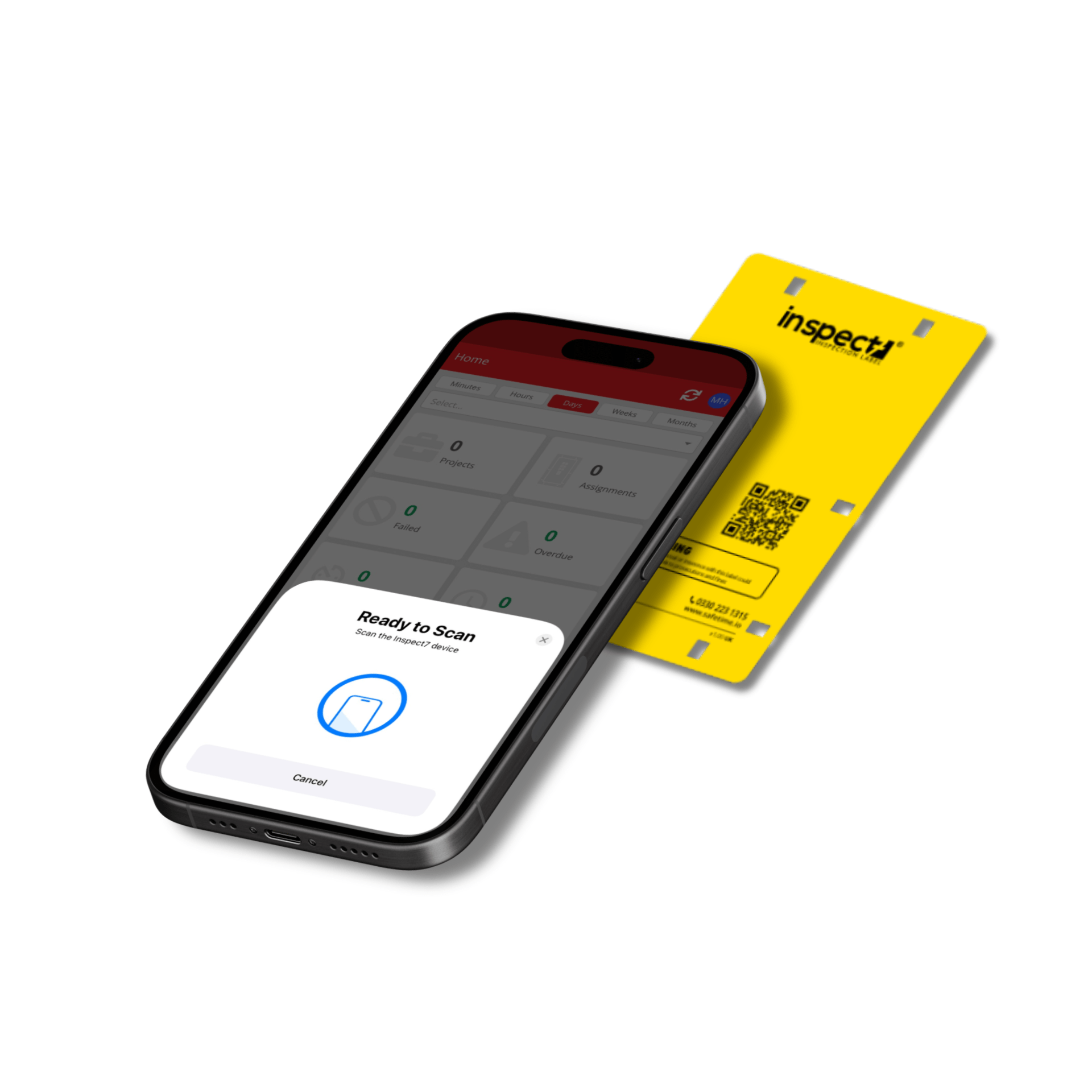

Just scan and inspect. The Inspect7® devices utilise NFC (Near Field Communication) so all the equipment required for an inspector is a mobile device/tablet signed in to the Inspect7® mobile app. This technology also creates transparency through Guest Access. When enabled, any device with the Inspect7® App can scan the devices to see the last inspection data, meaning an entire workforce can check that a ladder is safe to use.

Bronze and Silver subscribers get access to a Custom Questionnaire which allows an organisation to create tailored inspections to their standards and the ladder manufacturer’s recommendations. Gold and Platinum users can generate more questionaries so inspections can be tailored to different ladder types and manufacturers’ requirements.

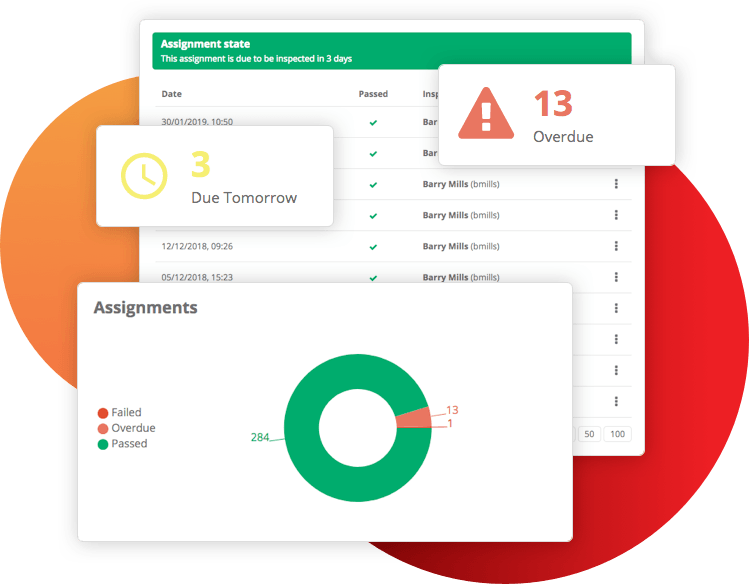

Never miss an inspection again by setting the required inspection intervals that match the manufacturer’s recommendations for your assignments. This will trigger an alert to remind you if an inspection is overdue. From the dashboard within Inspect7®, you can view the status of all the assignments in your projects so that you can ensure that every inspection is conducted and the safety of your equipment.

Within Inspect7®, comments can be left within Inspections, Assignments or Tasks. This can be directed to other users invited to that project by either including their @name or assigning them to a Task. When a user is tagged, they will receive a notification which means a team on a project can communicate effectively all through Inspect7®. For example, if during an inspection, damage is found on a ladder, an inspector can tag a manager or another college who can remove and replace the ladder directly within the app resulting in a replacement being ordered quickly.

Need more information?

For more information on Inspect7®, we offer a free, no-obligation demo. We will happily answer any questions you have about the system during the demonstration. Click the button below to book your demonstration.

Book a Demo