What is Safety Decking?

Safety decking, platform decking or crash decking as it is commonly known, is a fall arrest/work-at-height safety system platform that is constructed using boards which are laid horizontally and placed onto a framework created with vertical supports. Some Safety decking systems only require three components, panels, legs and universal non-slip plates making it a quick and easy to erect system. Due to this safety decking can be a preferred solution to traditional scaffold birdcage structures. Other variants of safety decking are available with different materials and construction complexity to withstand stronger weight loads.

Safety decking should only be installed by a competent person who has received sufficient training and understands the installation requirements set out by the manufacturer. This is where the first inspection should begin. Each component should be inspected to ensure that it’s not damaged or has a defect that can hinder its effectiveness. Every system should provide details of the inspection requirements for each component. All alterations to the safety deck should also only be completed by a competent installer.

The next inspection should occur before a handover. As stated in The Work At Height Regulation 2005 – Regulation 12 – Inspection of work equipment “Every employer shall ensure that, where the safety of work equipment depends on how it is installed or assembled, it is not used after installation or assembly in any position unless it has been inspected in that position”.

After a handover, it is the client’s responsibility to ensure that the safety decking is inspected again and then at regular intervals of no longer than 7 days. These inspections must be completed by a competent inspector with adequate training. It is also required that the system is inspected again after any adverse weather conditions, any events that may make the system unfit for continued use (fall of materials, debris, person etc.) or after any alterations which will require a new handover to be completed. This is to ensure that the system can continue to operate correctly and to ensure the safety of the workforce using it.

After every inspection, a report or copy must be provided “to the person on whose behalf the inspection was carried out”. These reports must be kept at the site where the inspection was carried out until the work is complete and the system has been dismantled. Furthermore, the reports must be filed and stored by the client for 3 months after completion.

How Inspect7® can be implemented?

The Inspect7® system is the perfect solution for safety decking inspections. Let’s start with the devices. Our devices are designed to fit directly onto scaffolding tubes with nothing more than a cable tie. The device can be secured directly onto the framework of the safety decking in a location that is easily visible and accessible to everyone on site including those who need access to the decking.

As the devices are waterproof to IP63 and designed to be rugged enough for the construction industry, they will withstand day-to-day conditions easily.

The visual indications will provide vital information daily to the workers using the decking. Load class information is available so that the weight limits of the decking aren’t breached and the inspection results at a glance will prevent incorrect usage keeping everyone safe.

Say goodbye to paper and hello to digital. Compatible with both iOS and Android systems, all the inspector needs to open the Inspect7® app and tap a device with their NFC-enabled mobile or tablet.

Utilising the custom questionnaires, you can ensure that a thorough inspection is carried out on the safety decking system which meets all requirements of the governing bodies and the manufacturers. Inspection time scales can also be set to every 7 days once the decking has been inspected after assembly to match these requirements.

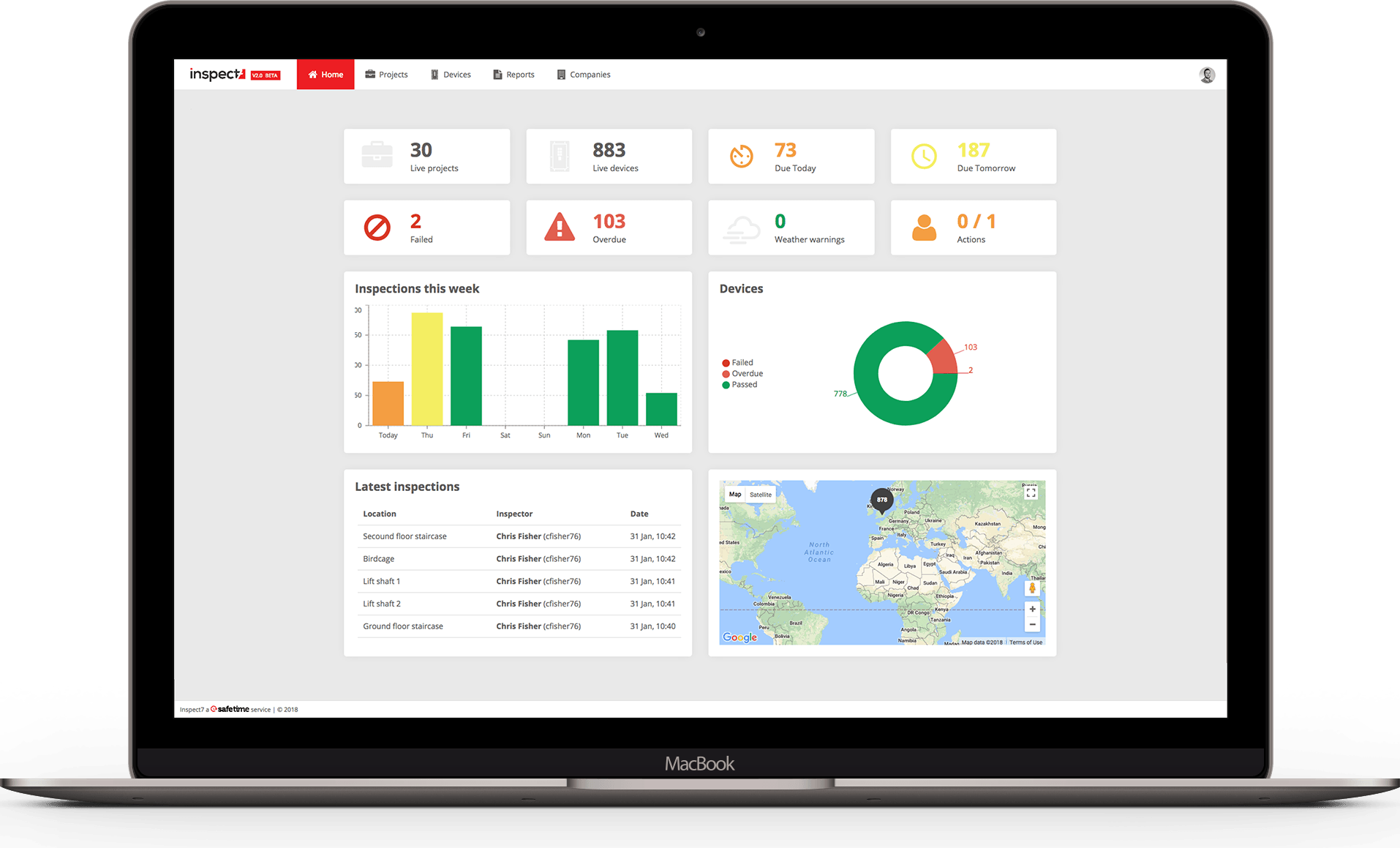

Using the online web portal, an authorised user can access all the inspection information of all devices registered to that project. Here a visual dashboard provides key device data such as due, failed and overdue inspections to help prevent any oversight. That way you have peace of mind that the correct people are doing the correct inspections at the set intervals.

All this information is sent to project users in the form of a Daily Digest. Using the location data of the devices and connecting data from weather sources, Inspect7® is able to alert you when there has been a meteorological event that may affect your decking, allowing you to conduct an immediate inspection.

The online web portal also allows guests to view the status of the inspections, so once the decking is set up, anyone using the decking can check its status to ensure it is safe for them to carry out work using the equipment. This also extends to client access so that you can have complete transparency with your clients.

All the inspection reports are stored in the system for future use. They can be turned into reports for self-evaluation on all your projects or shared digitally with whoever requires them.

Using our task system, reporting issues or damage to the safety decking can be conducted by any member of staff given access to the project. They can either tap the device with the App or use the web portal to add a task. A title, description, images, required date and comments can all be added to the task. This can be assigned to the inspector (or whoever else is required) and our notification system will send a push (App) notification and/or email.

Tasks aren’t limited to just issues. Need a different access solution? Assign a task to the correct person. It’s simple to use our system for more than just inspections.

To find out more about how you can implement Inspect7® into your business, book a free online demonstration.

Book a Demo